Trending

Popular Posts

Everest Headed For Another Record Year

April 12, 2024

Annapurna: More Summits, Two Women Without O2

April 15, 2024

Climbers Summit Annapurna, Head Down After Dark in Long Day

April 12, 2024

Stone Age Women Buried Alive in Ritual Murders

Archaeologists have discovered the remains of several ritual Stone...

Everest: Icefall Open but Climbers Advised to Hurry Through It

The route through the Khumbu Icefall has finally opened....

Ancient Greek Gladiator-Style Helmet Unearthed in Croatia

Burial mounds in coastal Croatia could help rewrite the...

U.S. Ultrarunners Aim For FKTs on Pumori and Lhotse

Last year, ultrarunner Tyler Andrews of the U.S. went...

Eric Larsen on Why He Decided to Lead a North Pole Tour Through Russia

Yesterday, polar guide Eric Larsen returned to Colorado after...

Everest Climbs Delayed: What’s Going On With the Khumbu Icefall?

We're already in the second half of April and...

Climate Change Plays Havoc with Trees’ Internal Clocks

Most people associate circadian rhythms and internal clocks with...

Weekend Warm-Up: Sarcasm, Humor, and the First Ascent of Sura Peak

The trouble on Sura Peak, at first, was that...

Must-See Documentary: ‘Champion of the Race,’ the Story of Major Taylor

Major Taylor broke more than 30 world records and...

A Conversation With Alex Honnold About His New Series, ‘Arctic Ascent’

BY ALEXANDER HARO

On a Tuesday afternoon in August of...

Weekend Warmup: Adam Ondra tackles Czech Sandstone in ‘Lords of Trad’

The big walls in Yosemite and the Alps are...

Weekend Warm-Up: Two Generations Bond on El Cap in ‘Free as Can Be’

Don't meet your heroes. That's how the old saying...

‘Searching for Christmas Tree’: An Ice Climbing Alternative to ‘Home Alone’

This Chinese climbing doc has nostalgia, mystery, and an...

Weekend Warm-Up: Climb, Paraglide, and Cycle Through the Alps With ‘North 6’

There are six north faces in the Alps that...

Weekend Warm-Up: ‘Calypte’: Sailing & Surfing Around the World

BY ALEXANDER HARO

This review first appeared on The Inertia.

Torren...

See the Winners of the World’s Best Adventure Sports Photo Contest

For the first time, a woman has won the...

Weekend Warm-Up: Bikepacking The Balkans — In The Style of Wes Anderson

It began as a review of a film.

Our intrepid...

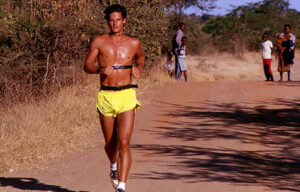

Brit Who First Ran Length of Africa in 1998 Calls Current Controversy ‘A Storm in a Teacup’

Nicholas Bourne, a British runner who ran the length...

Updated: Ultrarunner Completes Length of Africa — But Was He the First?

Today, Russ Cook finished his south-north run along the...

The Great Himal Race: 1,700 km From Tibet to India

The Great Himalayan Trail is a monster trek, the...

560 Miles in 6 Days: Camille Herron Sets New Women’s World Record Run

American ultrarunner Camille Herron has set another world record.

This...

French Cyclist Completes 1,400Km Midwinter Ride Across Lapland

Joffrey Maluski of France has cycled 1,436km across Lapland...

Chinese Organizers Jailed Over 2021 Ultramarathon That Killed 21 Runners

An infamous 2021 ultra-marathon that tragically killed 21 people...

Novice Kayaker Shatters 30-Year-Old Record on Australia’s Longest River

Dave Alley doesn't consider himself a kayaker. Yet the...

Weekend Warm-Up: Kilian Jornet is ‘Nnormal,’ and Also Isn’t

Kilian Jornet has been designing gear since he was...

Long-Distance Legend: Meet the Man Who Skateboarded Across the U.S. 5 Times

This article was originally published on GearJunkie.

Unsteady, vibrating skateboard...

Bonhomme’s Injury Forces Him to Abort Trans-Alps Run

As we reported earlier this week, Paul Bonhomme set...

Paul Bonhomme Sets out to Run the Length of the Alps

Mountain guide Paul Bonhomme has set out to run...

Nives Meroi Clears Up Their Kangchenjunga Plans

Peter Hamor, Nives Meroi, and Romano Benet's upcoming expedition...

Hamor, Meroi, and Benet Back to Kangchenjunga

Old rockers never die, they say, and veteran alpinists...

Benjamin Vedrines on the Historic Dru-Droites-Jorasses Trilogy

The international climbing community is starting to comprehend the...

Shkhara Team Delays Climb, Warms Up on Unnamed Peak

A few days ago, the Hungarian National Climbing Team...

Shkhara Winter Expedition Reaches the Glacier

The Hungarian National Climbing Team has started its winter...

New Route for Sieberer and Waldner on Schrammacher’s North Face

There is still room for true adventure and new...

Winter Expedition Heads to Georgia’s Highest Peak

The Hungarian National Climbing Team is heading to Georgia...

Winter Dolomites: New Route On The East Face of Civetta

Contrary to last season (which was very dry), the...

Two Rescues: On an Austrian Mountain and in a Slovenian Cave

Five days ago, there was a difficult, 15-hour rescue...

Trapped Caver Mark Dickey Survives ‘Hell’ of an Ordeal

Mark Dickey has emerged from the Turkish cave that...

Elaborate Rescue Continues for Caver Trapped 1,000m Down

Deep in the chambers of a renowned Turkish cave,...

‘I Didn’t Want to Leave’: Woman Spends 500 Days Alone In Cave

Beatriz Flamini might be the Michael Jordan of living...

A Trauma Doctor Analyzes the Thai Cave Rescue: ‘Nothing Short of Miraculous’

You probably already know the story.

In 2018, 12 juvenile...

World’s Most Prolific Cave Explorer Dies at 80

Marion Smith, a caver with 8,291 separate explorations to...

Tourist Ignores Warnings, Dies From Falling Ice in Ushuaia Cave

A mass of ice fell from the ceiling of...

Nearly 300 Volunteers Rescue Stranded UK Caver

In the early afternoon of November 6, 2021, 38-year-old...

The Annamites: Vietnam’s Unknown Mountains

The Annamites don’t boast any towering snow-capped peaks. They...

Weekend Warm-Up: Changabang: Return to the Shining Mountain

New Zealand alpinist Daniel Joll leads off Changabang with...

Legendary Mt. Rainier Guide Lou Whittaker Dies at 95

A Mount Rainier icon has lapsed into the alpenglow.

The...

Here’s How Rare No-O2 Climbs on 8,000m Peaks Have Become

As the climbing season starts in the Himalaya, we...

Gunther Messner’s Second Boot Returns to Reinhold

Reinhold Messner has finally received the second boot of...

Great Tales in Mountaineering History: Panch Chuli, 1992

In the summer of 1992, an Indian-British expedition headed...